|

|     | PCCNC / Flexibility

| | |

Engelhardt CNC Series PCCNC

| The modern and flexible solution

PC based continuous path control of between two and eight servo or stepper motor axes (or for mixed operation), which can simultaneously be controlled through an interpolation pro-cedure. The standard software includes linear, circular, and helical interpolation. Programming according to DIN 66025 with convenient menu and flexible subroutine technology. Program Syntax check. Integrated parameter programming is available to you for the calculation of geometrically complex paths. Also included are fixed and user-programmable processing cycles, tool administration and compensation.

All text informations and error messages are stored in ASCII files which can be changed by any text editor. So a adaption to a foreign language is very easy. Even the text informations of a individual menue are switched to the foreign language by machine data.

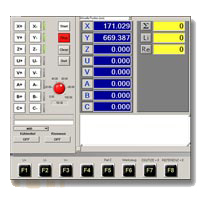

The standard delivery of the PCCNC includes a 19" rack, operating system WinXPpro and a capable graphik user interface. Included is a status display of up to 64 I/O and 16 axle limit switches which makes it easy to do the setup of the CNC. For customizing of the CNC there are the fpllowing features included: Call of 8 programs in Hand- and Automaticmode by function keys. Up to 8 additional numeric displays with grfik symbol and value to display f.e. workpiece counters or execution time. Input of parameters by variable poup menus. Display of pictures (.jpg .bmp...)f.e. to illustrate the meaning of menu parameter inputs or give assitance to the worker how to mount the workpiece.

Basic functions like travel to reference point, Handmode, supervising of the limit switches, lag diffrence and In position error are includes in the software.

The Interpolator has a buffer memory for 200 blocks which is continously reloaded during the operation.

Equipment of the PCCNC:

•Intel CPU up to 1.8 GHz

•HDD up to 120 GB

• 2* PS/2

• 2* USB Interface

• 1* RJ45 Ethernet

• 1* VGA

• Interpolator cycle time 2 msec, position controller cycle time 200 µsec, high path and positioning accuracy

• Precontrol of speed to minimize lag distance

• Up to 64 inputs and outputs can be controlled in the CNC program. Setting and resetting the outputs without stopping the axes

• Fully-automatic tool radius and length correction

• Speed-dependent analogue output (optional)

• Speed-dependent pulse output max. 200Hz (optional)

• Continuous travel with all types of drive

• 2*V24 Interface: For connection to an external manual control unit

• connectors for external rotary position transducer or glass measuring scale

• connector for a joystick

|  User Manual User Manual |  Data Sheet Data Sheet |

|

|

|